Green Body Density Measurement Techniques

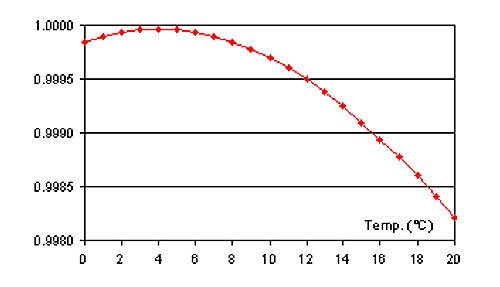

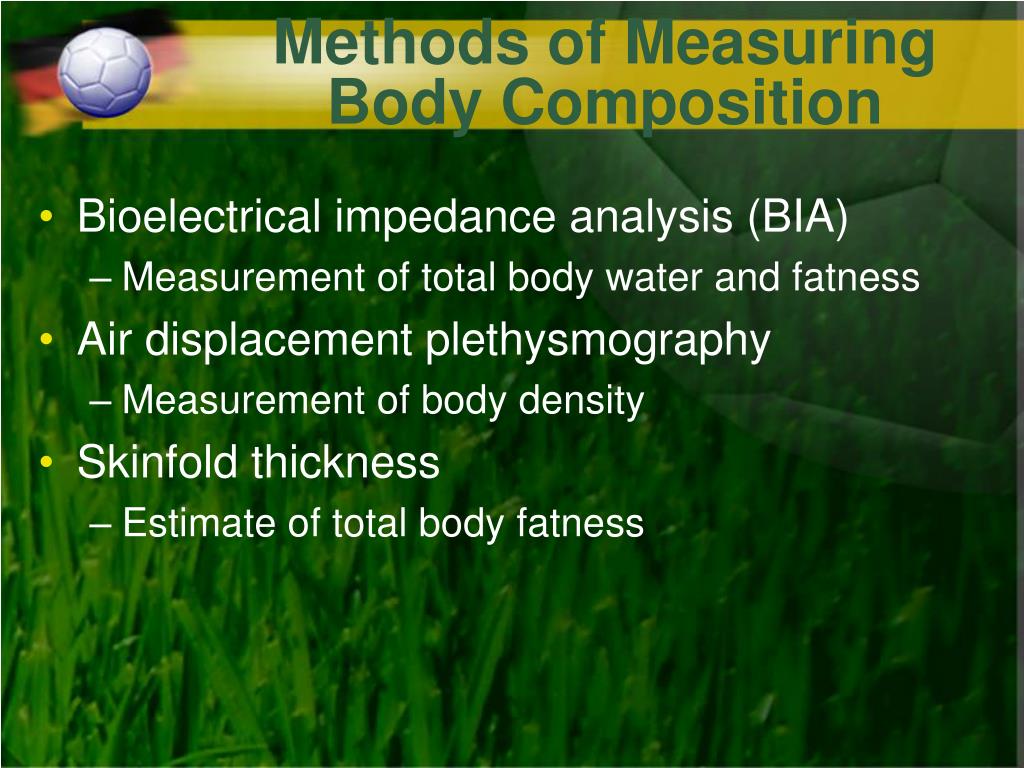

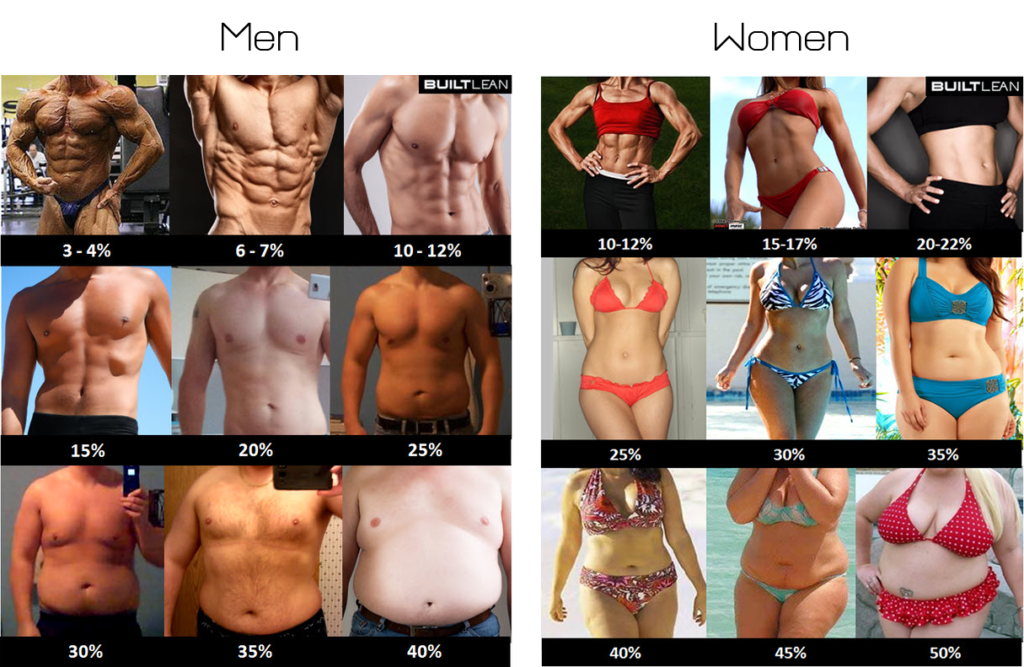

Essentially the same differences have been confirmed by hydrostatic weighing body density as measured by whole body immersion in water skin fold thickness anthropometry dual energy x ray absorptiometry electrical impedance proton magnetic resonance spectrometry tbw measurement by isotope dilution and air displacement plethysmography buffa et al 2001. Introduction the ceramics industry is interested in increasing ef. The green body density feld of a truncated cylinder made of alumina powder is evaluated using this method and the reconstructed feld is presented. Abstract green body density measurement techniques were investigated and compared. The measurement techniques investigated include mass volume measurement mercury pycnometry powderdisplacement pycnometry and noncontact ultrasonic method. The porosity of freshly pressed ceramic bodies governs green tile behavior during the process drying glazing and firing and largely determine the properties of the final product.

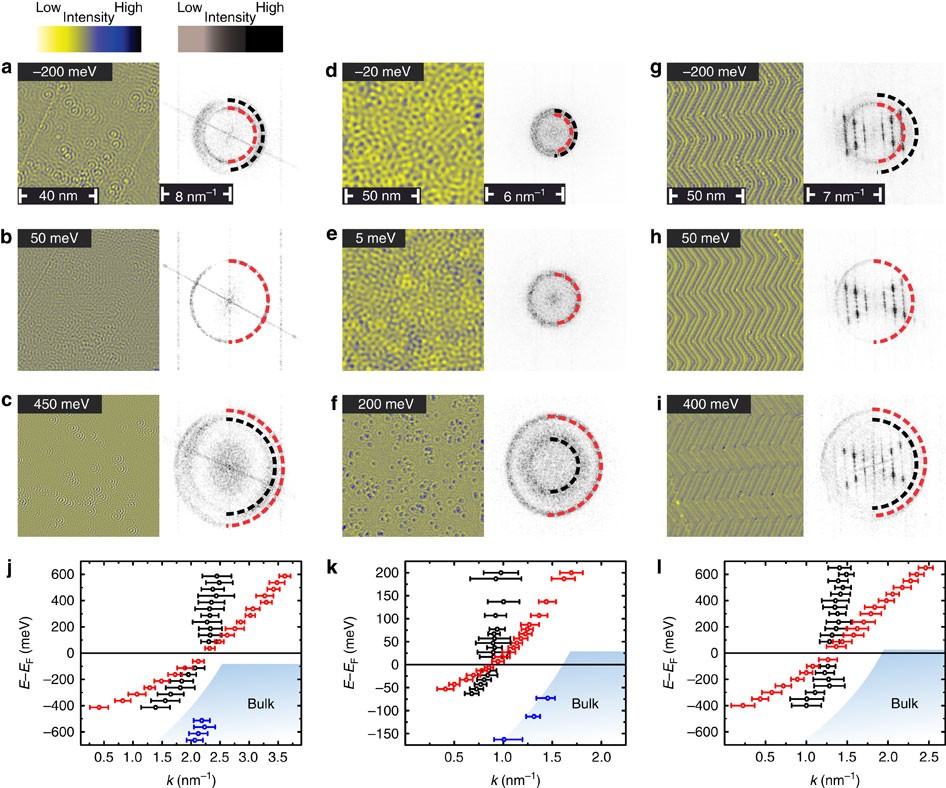

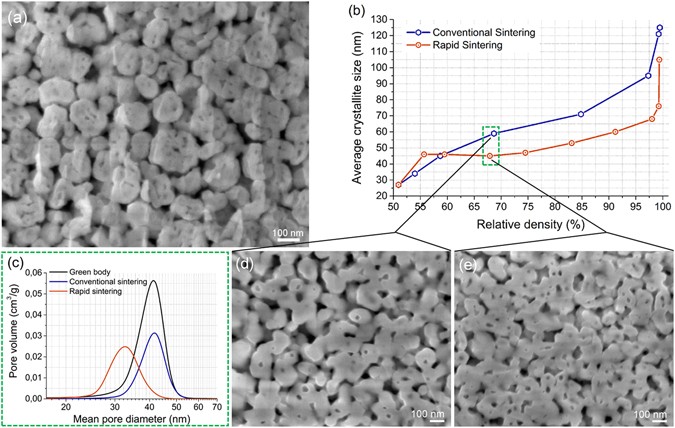

This method uses non contact ultrasonic probes. This can also be used to measure bulk density of green clay body chips which would with other techniques break down under water or xylene. The green body was formed under a mean axial stress of 120 mpa which is slightly more than the supplier recommended 100 mpa forming pressure to attain a green density of 24 g cm 3. The bulk density of a green ceramic body provides. Tomography density evaluation techniques mechanical densifcation green bodies 1. Fields et al 2001 2002.

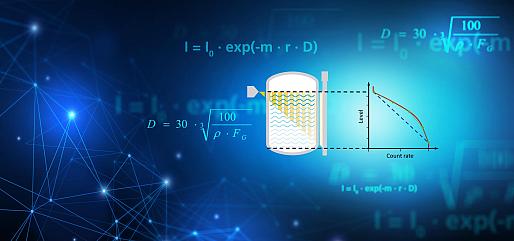

The bulk density of a green ceramic body provides valuable information needed to control the quality of a ceramic piece after firing with respect to its final size and the porosity and cracks in the body and is proportional to the final mechanical. The measurement of bulk density of for example green ceramic tiles during production is a fundamental parameter for the quality of the product. The work presents an innovative method for non intrusive measurement of the apparent density of green ceramic tiles during the production stage. This will cause bonding mechanisms to occur between powder particles pressed together in the compact. The ultrasonic direct transmission density measurement. Powder sintering involves raising the temperature of the green compact pressed powder part to a certain level and keeping it at that temperature for a certain amount of time.

The measurement of bulk density of for example green ceramic tiles during production is a fundamental parameter for the quality of the product. The analysis took advantage of the symmetry of the green body along the diameter thereby yielding two mirror images of the sample. Correspond to the original solution. Density or grain density iso 8840 and sans 5904. Crossing and cross correlation techniques fig. The sintering temperature is usually between 70 and 90 of the melting point of the powder metal.

Random Post

- galina dub body measurements

- body measurement chart for weight loss printable

- bra size measurement centimetres

- curvy body shape measurements

- ishan khattar body measurement

- vedhika kumar body measurement

- what is my body type by measurement

- emma mackey body measurement

- uzi body measurement

- phoebe tonkin body measurement

- body measurement cm

- lavanya tripathi body measurement

- us body measurement conversion

- lucy liu body measurement

- umme ahmed shishir body measurement

- human body measurement chart

- body measurement guide for sewing

- zara mcdermott body measurements

- jenna gray body measurement

- gisele bündchen body measurement

- body measurement dq11

- azzyland body measurement

- ideal body measurement for 5'4 female

- body measurement jsa

- human body measurements opencv

- chris pratt body measurement

- jessica lucas body measurement

- giannis antetokounmpo body measurement

- how do bra measurements work

- body frame size measurement

- bra size dd means

- sugandha mishra body measurement

- auto body shop measurements

- bra size band

- web body measurement

- body measurement rosamund pike

- juliana semenova body measurement

- body measurement graphic

- rcl beauty body measurements

- bra measurement chart us

- rpf body measurements

- bad body measurement

- body shape based off measurements

- titus o'neil body measurement

- andrew taggart body measurements

- bharti singh body measurement

- roshna ann roy body measurement

- priyanka chopra height body measurements

- kpop ideal body measurements

- nusrat faria body measurement